VDOT : Signal Back Plates

[ Download ]

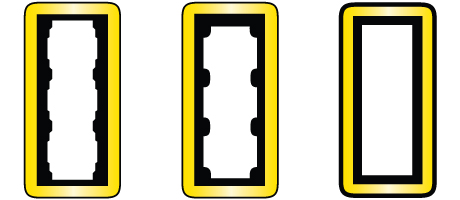

The latest technological advance in signal back plates is here, the Korman Signs LIGHTHAWK Series. They are made from ALPOLIC® 350, a proven lightweight aluminum composite material, and 3M™ Diamond Grade Cubed (DG3) state-of-the-art reflective sheeting to produce a twelve year finished product. No longer do you have to worry about fading, cracking, & peeling failures. The LIGHTHAWK brand back plate is manufactured and made in the USA by Korman Signs, Inc. and can be fabricated to fit any signal head assembly.

Lighter than plastic or aluminum - 2mm thick at .57 lbs/sqft

Thicker and structurally stronger than conventional material

3M DG3 Sheeting is the brightest technology available from any angle

Fluoropolymer finish and relfective sheeting both provide 12 year life

Any brand, size, fit and shape via CNC machining operation

Fluorescent yellow yields ultimate intersection awareness, day or night

Wind tunnel and nighttime field demonstration

Very low net life cost investment

Made to meet any DOT spec

The LIGHTHAWK ALPOLIC 350 Back Plates are furnished with a variety of reflective patterns, grades, and widths.

A number of studies have confirmed the safety value of reflectorized signal back plates. The LIGHTHAWK ALPOLIC 350 Back Plates are an innovative and more effective approach to fulfilling the goal of improving intersection safety and reducing accidents. The weight to structural strength ratio of the ALPOLIC 350 and the high perfomance of the 3M reflective sheeting is unmatched and virtually prolongs the need of maintenance for the life of the signal light assembly itself.

[ Download ]

[ Download ]

[ Download ]

[ Download ]

[ Download ]

For additional information on LIGHTHAWK ALPOLIC® 350 Back Plates please contact the office and our customer service representatives will gladly provide more information on your options - Email Us or call (800) 296-6050.